- Optimize Your Water Usage – Schedule Your Free Expert Consultation!

- Contact Us Now

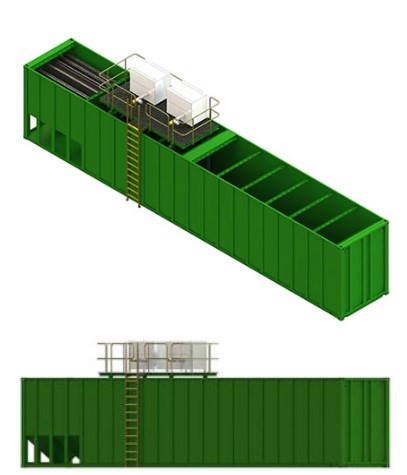

Sewage Treatment Plant is a system for treating sewage (domestic wastewater) with the aim to remove contaminants from it, thus making it fit for reuse or disposal.

Vulture Innovation does provide STPs based on all major technologies based on project requirements and Clint’s preferences

Moving bed bioreactor (MBBR) is a technology for treating both municipal and industrial wastewater, whose principle of technology is based on Attached Growth on Suspended Media (biomass grows on inert media suspended in tanks, leads to higher biomass retention, and thus higher BOD removal). The important component of this system is the bio-carrier on which bio-film grows continuously throughout its entire surface under dynamic conditions. The application of this technology can be used for the wastewater treatment of the municipal, residential societies, Township, commercial building, any industrial non toxic wastewater

The membrane bioreactor (MBR) has emerged as an efficient compact technology for municipal and industrial wastewater treatment. MBR technology has emerged as a wastewater treatment technology of choice over the activated sludge process (ASP) or microbiol BOD degradation system coupled with microfiltration or ultrafiltration membrane systems. MBRs differ from ‘polishing’ processes where the membrane is employed as a discrete tertiary treatment step with no return of the active biomass to the biological process.

Almost all commercial MBR processes available today use the membrane as a filter, rejecting the solid materials which are developed by the biological process, resulting in a clarified and disinfected product effluent.

The Sequencing Batch Reactor (SBR) is a different conventional activated sludge system, in which the process can be operated in batches, The process of ASP broken into batches offering better process control and easier anoxic-aerobic cycles.

The treatment consists of a cycle of five stages: fill, react, and settling, decanting and idle. During the reaction type, oxygen is added by an aeration system. During this phase, bacteria oxidize the organic matter just as in activated sludge systems. Thereafter, aeration is stopped to permit the sludge to settle. In the next step, the water and the sludge are separated by decantation and the clear layer (supernatant) is discharged from the reaction chamber. The application of this technology can be used for the wastewater treatment of the municipal, residential societies, Township, commercial building, any industrial non toxic wastewater.

Upflow anaerobic sludge blanket technology also known as UASB reactor Anaerobic Wastewater Treatment is a wastewater treatment system using biology without using air or oxygen. It aimed to remove organic pollutants in wastewater, slurries, and sludge. Anaerobic microorganisms convert organic pollutants into “biogas” which contain methane and carbon dioxide. Anaerobic decomposition of organic pollutants producing CO2 and CH4. The application of this technology can be also used for the wastewater treatment of municipal, and residential societies, townships, commercial buildings, and any industrial non-toxic wastewater.

Medical

Waste and sewage management is one of the grave concerns that our country is facing today, as it is posing health risks and threatening natural water resources. Hence, adopting a Sewage Treatment Plant (STP) becomes inevitable for municipalities, residential societies and industries.

STP is a sewage water treatment plant that purifies wastewater to make it fit for reuse. It collects wastewater from households or industries and treats it in multiple stages. The main goal of a sewage water treatment plant is to remove contaminants like organic matter, pathogens and chemicals from the wastewater. The STP water can also be used for irrigation.

An STP water treatment plant follows a series of steps that are designed to ensure the purity of water. This is a long process that involves multiple steps:

In preliminary treatment, the sewage water passes through a series of screenings where large objects like debris are removed. After that, the water flows through a grit chamber, where inorganic wastes are separated.

In primary treatment, the water is allowed to sit in a large tank for some time. This lets the heavier particles settle down at the bottom. In the sewage treatment plant process, even the lighter materials like oil and grease are skimmed off.

The secondary treatment is used to remove dissolved and suspended organic matter through biological treatment. It uses activated sludge and filter beds process where the good bacteria in the sludge break down the pathogen in the sewage water. This removes almost 90% of the pollutants in the water.

The tertiary treatment is used to further purify and remove remaining pollutants in the water. Here the water passes through a fine filter and chemicals and disinfectants are added to clear remaining contaminants like harmful bacteria, pathogens and viruses.

Installing a sewage treatment plant in India can be beneficial for both the environment and society. Here’s how:

STP water treatment helps reduce pollution by treating sewage water before getting discharged into the environment. This also prevents the spread of harmful pollutants in the ecosystem.

Sewage contains harmful pathogens, treating them in the STP treatment plant eliminates these microorganisms. This helps reduce the risk of waterborne diseases and preserve public health.

Wastewater treated in sewage treatment plant is safe enough to be used. Hence, reusing water for agricultural, industrial and irrigation purposes reduces the demand for fresh water. It saves water to a large extent.

The untreated sewage water contains harmful bacteria and chemicals that pollute the environment. The STP plants effectively remove organic waste and other toxins present in the water.

The water treated from sewage water treatment plants can be used for agricultural purposes, by converting the sludge from the treatment into compost. Additionally, the sewage treatment plant requires skilled labourers for maintenance and operation which creates jobs in the community.

Vulture Innovation is the best sewage treatment plant manufacturer in India for various reasons. They have cutting-edge technologies that are innovative, highly scalable and energy efficient. The materials of their plants are of standard quality and highly durable. Their team of experts understands the client’s requirements and guides them according to their needs and budget. All these aspects together make them one of the best sewage treatment plant suppliers in India.

STP stands for a sewage treatment plant which involves treating wastewater from households and industries. This removes contaminants and pollutants from wastewater through a series of physical, biological and chemical processes.

The primary purpose of the STP plant is to collect and treat wastewater to purify it. It eliminates harmful substances and pathogens from the water to make it fit for use.

Vulture Innovation is committed to become the one stop solution for all your waste management requirements. Be it biodegradable or non-biodegradable, solid waste or waste water; we have the innovative and technological capability to provide you with most sustainable solutions for effluent management.